Streamlined PO to discipline delivery

Ashwini December 5, 2023

With long lead times in production, you depend on ‘demand forecasting’ that often proves wrong. A lot more inventory than is necessary blocks working capital. You also cannot produce repeat orders fast enough to capitalize on sale opportunities.

Eventually, you don’t stand to gain a competitive edge.

‘Pravah’, our supply chain transformation solution, gets more jobs done faster in Manufacturing.

It reduces production lead times substantively by applying scientific methods that govern processes of procurement, production scheduling and shop floor practices.

You are able to reduce dependence on Demand forecasting by integrating execution into planning much closer to real demand.

‘Pravah’ draws upon principles of the powerful business improvement science of ‘Theory of Constraints’.

A bottleneck could be a machine, process, or work center that sets the top limit on your output

Examine and sharpen the batching time, queueing time vis-à-vis the actual time it takes to produce goods

Configure buffers for inbound raw materials, components, and semi-finished assemblies/WIP so bottleneck machine is never left idle

The machines/work centers swing into action on depletion of the inventory buffer to a pre-set degree.

Synchronizing flow of WIP across the production line in a smooth manner cuts down on response times substantively.

You will be able to deliver OTIF- On time in full- in 90%+ cases.

Synchronized inventory across RM, WIP and FG releases much needed working capital.

An easy-to-follow color-coded priority system eliminates firefighting and chaos on the shop floor.

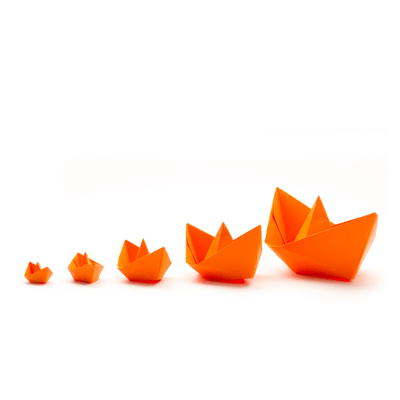

Reap the benefits of quick-on-foot production to build a competitive edge for yourself.

We will handhold you in introducing and implementing the change that ‘Pravah’ brings your way.

WIP release to shopfloor| Min batch size | Holistic output versus local efficiency

Inventory mix in Raw Material & WIP vis-à-vis FG